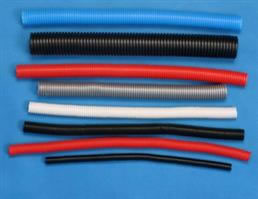

Corrugated halogen-free conduits with UV-stabilisation Corrugated one-wall pipesfor power cables and wires protection and insulation in direct UV exposure and inside the buildings. UV stable pipe designed for mechanical protection of all kinds of power and data wiring.Suitable for outside instalation. Pipe is available with pull-out wire as well. It is used in premises where human resources and valuable property protection, damage minimization in case of fire, further on it is used for machinery, public buildings and railways.Suitable for housing and industrial distribution in hospitals, schools, IT centers, etc. Suitable for environments with increased need of people and equipment protection. Also Suitable for installing in dangerous zone 2 in explosive areas.

Application area:

Mechanical protection and insulation of power cables and wires during the establishment of:

• Safe connections and installations at electric power substations;

• Cable connections between storeys;

• Connections of buildings to electrical power networks;

• Transition of overhead lines to underground cable networks;

• Mechanical protection of power cables inside buildings. Physical properties:

• Long term UV resistance (more than 10 years);

• Self-extinguishing, designed for installations in public buildings;

• Increased fire resistance;

• Low smoke emission;

• Made from flame retarding PP-based compound;

• Temperature resistance from -40° C to +90° C

• Long-term durability and abrasion resistance;

• Pipes provide long-lasting, corrosion-free service;

• No need for servicing (repainting, removal of rust);

• Quick and cheap installation;

• With pulling wire. Anti UV PVC corrugated pipe produced in coil lengths of 25 and 50 metres with pre-installed pulling wire. Each coil is fixated with polypropylene band. Coils are positioned on pallets and stretch-packed for comfortable handling.

Flexible, excellent tenacity and high mechanical strength.

Luster in surface and Insulation.

• wind resistant;anti-friction; resistant to oil,acid and solvents;uv-resistant.

• free of halogen,phosphor and cadmium.

• They are very light, which makes it easier to assemble and transport them.

• Their smooth internal surface makes I t easy to insert the cables inside the pipes

• They have excellent mechanical and physical features

• They are resistant to impact, as well as impermeable to water and dust

• They are long lasting, and without need for maintenance

• flexible pipes make possible continuous placing and are very adaptable to the demands of the terrain; also these pipes are very cost saving.

• they are used at temperature range from -40°C up to +80°C

• they are highly resistant to corrosion

• Light material, easy and quickly to storage and manipulate

• Easy to transport, simple and cheap assembling process

• The process of connecting two PVC pipes doesn’t last for more than 1 minute, there for the interruptions of the traffic do not last very long

• They have thin walls, so that the laying of the cables inside the pipes is very swift and simple

• In the same trench a large number of pipes can be laid next and on top of each other

• Connections are impermeable to water and any other fluids

• They are resistant to corrosion in alkaline, acid or any other aggressive environment

• They are fine electrical insulators and also resistant to stray currents

• They’re resistant to impact

• They are resistant to ageing (with the life time of more than 50 years)

Application

A flexible electrical installation conduit made of a special, halogen-free material and ideally suitable for outdoor installations exposed to direct sunlight. The conduit has a sheath made of a plasticised material which is specially modified for resistance against UV radiation. The conduit features the highest degree of impact strength. The special structure of the inner surface of the conduit with outstanding gliding properties allows to considerably extend the cable-pulling distances and reduce the length of installation work. The colour of the sheath of the conduits is black (RAL 9004), with an orange inner gliding layer. Physical properties: Material: a special, halogen-free material, high limit load, high impact strength, temperature resistance from - 25°C to +105°C, UV-stabilised, self-extinguishing, corrosion-resistant. Application area: The conduits are specifically recommended for outdoor installations, can be used for installations in hollow walls, partitions, or suspended ceilings in public buildings: schools, kindergartens, hospitals, hotels, theatres, cinemas, museums, stadiums, arenas, shoppingcentres, airports, railway stations, and office buildings. The conduit withstands long-term exposure to sunlight. UV-resistance is guaranteed for 10 years. Especially suitable for protection of facade lighting cables.

History

Some early electric lighting installations made use of existing gas pipe serving gas light fixtures which had been converted to electric lamps. Since this technique provided very good mechanical protection for interior wiring, it was extended to all types of interior wiring and by the early 20th century purpose-built couplings and fittings were manufactured for electrical use.

However, most electrical codes now prohibit the routing of electrical conductors through gas piping, due to concerns about damage to electrical insulation from the rough interiors of pipes and fittings commonly used for gas.

Comparison with other wiring methods

Electrical conduit provides very good protection to enclosed conductors from impact, moisture, and chemical vapors. Varying numbers, sizes, and types of conductors can be pulled into a conduit, which simplifies design and construction compared to multiple runs of cables or the expense of customized composite cable. Wiring systems in buildings may be subject to frequent alterations. Frequent wiring changes are made simpler and safer through the use of electrical conduit, as existing conductors can be withdrawn and new conductors installed, with little disruption along the path of the conduit.

A conduit system can be made waterproof or submersible. Metal conduit can be used to shield sensitive circuits fromelectromagnetic interference, and also can prevent emission of such interference from enclosed power cables.

When installed with proper sealing fittings, a conduit will not permit the flow of flammable gases and vapors, which provides protection from fire and explosion hazard in areas handling volatile substances.

Some types of conduit are approved for direct encasement in concrete. This is commonly used in commercial buildings to allow electrical and communication outlets to be installed in the middle of large open areas. For example, retail display casesand open-office areas use floor-mounted conduit boxes to connect power and communications cables.

Both metal and plastic conduit can be bent at the job site to allow a neat installation without excessive numbers of manufactured fittings. This is particularly advantageous when following irregular or curved building profiles. Special equipment is used to bend the conduit without kinking or denting it.

The cost of conduit installation is higher than other wiring methods due to the cost of materials and labor. In applications such as residential construction, the high degree of physical damage protection may not be not required, so the expense of conduit is not warranted. Conductors installed within conduit cannot dissipate heat as readily as those installed in open wiring, so the current capacity of each conductor must be reduced (derated) if many are installed in one conduit. It is impractical, and prohibited by wiring regulations, to have more than 360 degrees of total bends in a run of conduit, so special outlet fittings must be provided to allow conductors to be installed without damage in such runs.

Some types of metal conduit may also serve as a useful bonding conductor for grounding (earthing), but wiring regulations may also dictate workmanship standards or supplemental means of grounding for certain types. While metal conduit may sometimes be used as a grounding conductor, the circuit length is limited. For example, a long run of conduit as grounding conductor may have too high an electrical resistance, and not allow proper operation of overcurrent devices on a fault.

Types

Conduit systems are classified by the wall thickness, mechanical stiffness, and material used to make the tubing. Materials may be chosen for mechanical protection, corrosion resistance, and overall cost of the installation (labor plus material cost). Wiring regulations for electrical equipment in hazardous areas may require particular types of conduit to be used to provide an approved installation.

Application:

Automotive wiring, machinery, machine tool automation instrument, electrical motors, protect the cable wires, automotive wiring harness, machinery, ships and rail transit can also be used for machine tools such as mechanical, automation instrument, electrical motor, wear is not affected by external forces and insulation protection cable wire. Wire casing, adornment casing, is suitable for liquid and oil transportation, power line protection, the protection of the automotive wiring harness, machinery, machine tool automation instrument, etc

Produce Process:

With Appropriate ratio of fertilizer mixing, it adopts "Z” type kneading machine and high speed kneading machine to mix it evenly, double screw extruder granulation or adopted powder forming at a time. Using a single screw extruder revolution generally is 30 ~ 60 r/min, the nose about 36 ~ 54 mpa pressure control. Material to fully plasticizing, use free compressed air blowing into bubble. After extrusion stability, insert corrugated molding device with extrusion die, be assured of the center line, extrusion die into molding mould should be greater than a module, to ensure that the top and bottom modules are all closed before molding products.

Production equipment and features:Extruder for isometric range commonly deep, the gradient type screw (see soft poly catch ethylene works extruder).Corrugated forming device is mainly composed of forming dies, transmission system and control system.The forming die is made up of dozens of split up and down continuously blowing mold, lower die to caterpillar respectively fixed on the two belts.When drive system driven in mold, mold repeated closed - open the action up and down. Constitute a circular pipe forming die closed cavity, after blowing molding corrugated pipe, open mold, can make the product mold release. Corrugated forming device products forming and the traction effect at the same time.PVC plastic corrugated wire tube adopts ZBG. 33008-89 standard.

UV-stabilisation Corrugated one-wall pipes

Anti UV PVC corrugated pipe

UV protection PVC corrugated pipe

UV-STOP PVC corrugated pipe

ultraviolet ray interception PVC corrugated pipe

UV-resistant PVC corrugated pipe

Anti-UV PVC solar corrugated pipe

PVC corrugated pipe with UV Stabilizers PVC flexible electrical corrugated pipes for UV-resistant

UV stable pipes